Deserved

On September 20th, the 6th China Innovation and Entrepreneurship Competition (Guangdong·Jiangmen Division) and the 2017 Jiangmen City “Tech Cup” Innovation and Entrepreneurship Competition were held in the Ten Friends Building of Wuyi University. The 27 companies that entered the finals competed for the Million Prize. After fierce competition, there are 2 enterprises in Heshan City, among which Guangdong Yajia New Energy-saving Polymer Materials Co., Ltd. won the third prize of the Growth Enterprise Group.

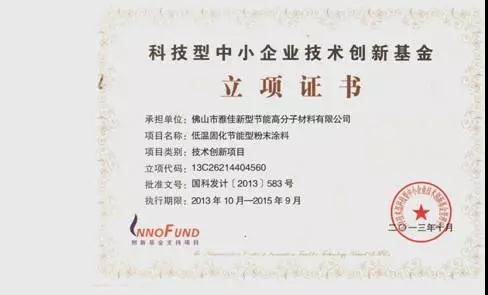

In the past six months, there were 13 companies (2 in the start-up group and 11 in the growth group) in Heshan City. After the preliminary competition, the rematch, the field trip and other aspects, Guangdong Yajia New Energy-Saving Polymer Material Co., Ltd. (enter project: low-temperature energy-saving powder coating) stood out in this competition and successfully entered the final of the growth enterprise group and finally won the third prize. And support funds.

Award-winning project introduction

Low temperature energy-saving powder coating

Low-temperature energy-saving powder coating is a new type of powder coating that reduces the traditional curing temperature of 200 °C/10mins to 150-160 °C/10mins or even lower. It has all the properties of general powder coatings. The curing temperature is lowered by 40-50 degrees. Therefore, it has the following typical characteristics:

1) Bake energy consumption is lower, reducing energy by 25%;

2) The equipment load is smaller and the life is doubled;

3) Lower carbon emissions, reducing emissions by 25%;

4) Lower exhaust emissions and greater environmental contribution.

Main performance indicators

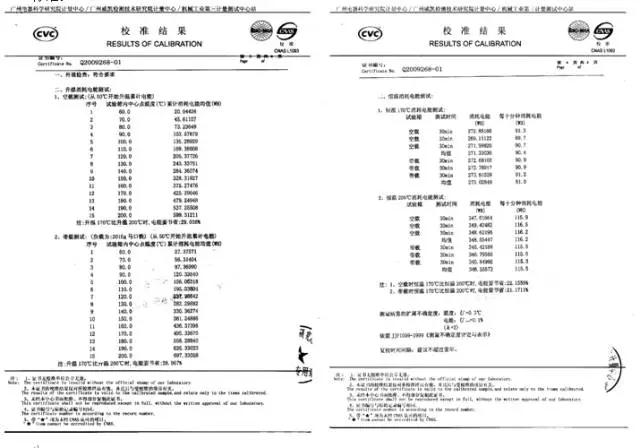

The low-temperature energy-saving powder coating is tested by authoritative departments, and its energy-saving effect is above 25%, and its performance indicators are in full compliance with national standards.

It is measured by energy consumption under the conditions of 170 degrees and 200 degrees.

The heating process can save 28% energy, the constant temperature process can save 21%, and the comprehensive energy saving effect reaches 25%.

The important weather resistance index of low-temperature energy-saving powder coatings is tested by authoritative third parties and fully complies with the national aluminum profile standard GB/T5237.4-2008

Project success story

1. In early 2010, Hisense Kelon fully used our company's low-temperature energy-saving powder coatings;

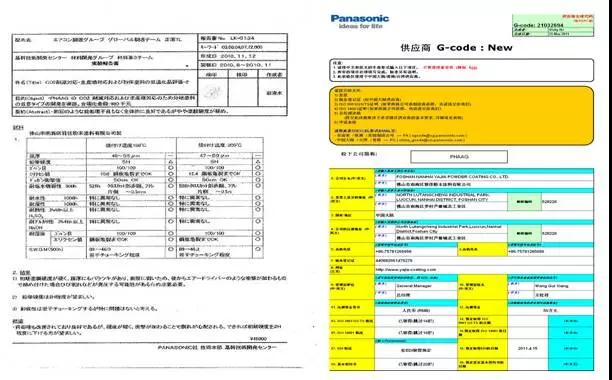

2. Thanks to Akai, the global supplier of Panasonic, in 2009, our company started to develop low-temperature energy-saving powder coating for Panasonic, and started to use it in 2011. At present, the coatings used by Panasonic are low-temperature curing powder coatings provided by our company, which can save Panasonic's energy consumption by about 400,000-500,000 per year;

3. In 2013, Midea's commercial air conditioners used our company's low-temperature energy-saving powder coatings.

Received strong support from Guangdong Science and Technology Innovation Fund

Industry and market analysis

1

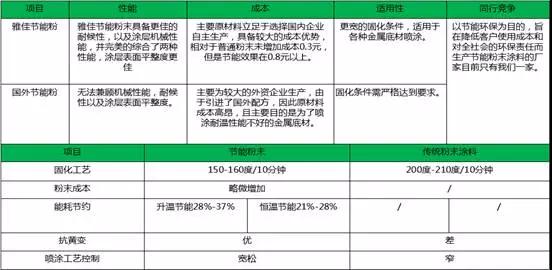

Product advantages:

Social Benefits: Taking aluminum profiles as an example, in the aluminum profile industry, the traditional 200-degree solidified powder coating 1 kg of powder needs to consume 1 cubic meter of natural gas energy during the solidification film formation process, which will produce 1.964 kg of carbon dioxide, saving energy-saving powder coatings. 25% of the natural gas consumption, that is, 1 kg of energy-saving powder only needs to consume 0.75 cubic meters of natural gas in the process of solidification film formation, only 1.473 kg of carbon dioxide, which reduces the carbon emission of 0.491 kg of carbon dioxide compared with the traditional powder coating, 1 ton of energy saving Powder can reduce carbon dioxide emissions by 0.491 tons. In Guangdong, about 300,000 tons of powder coatings are used each year, so energy-saving powder coatings can reduce the carbon emissions by 147,300 tons.

Economic Benefits: The current natural gas price is about 3.2 yuan / cubic meter. If we use 170 degree solidification energy-saving powder, we can save 0.8 yuan of natural gas per kilogram. The energy consumption per ton of powder can reduce the cost by 800 yuan. Excluding the cost per ton of powder increased by about 300 yuan, the cost per ton of powder can be reduced by 500 yuan for customers. For example, according to the annual use of 300,000 tons of powder coating in Guangdong, the use of energy-saving powder coating can reduce the cost by 240 million yuan.

2

Industry status and major competition:

At present, more than 90% of the national powder coatings still use conventional normal temperature powder coatings. Due to technical barriers, foreign low-temperature energy-saving coatings are expensive and cost-effective, so they cannot be promoted. After years of efforts, Guangdong Yajia has been able to achieve the full range. For the purpose of energy saving and environmental protection, Guangdong Yajia aims to reduce the cost of customers and the environmental responsibility of the whole society to produce low-temperature energy-saving powder coatings.

3

market expectation

China's traditional powder coatings are gradually replacing paints and solvent-based coatings with their green and environmental advantages. They are increasing at a rate of more than 7% per year. With the strengthening of environmental protection in the beginning of 2016, low-temperature energy-saving powder coatings More energy-efficient and more environmentally friendly features have sprung up in the market. The demand for low-temperature coatings by well-known large companies is growing. Therefore, low-temperature energy-saving coatings will gradually replace conventional powder coatings in the following years.

Customer Resources

Since its inception, Ajia has always adhered to the goal of domestic and foreign famous enterprises, as well as medium and high-end users, and is committed to the development and production of functional, medium and high-grade powder coatings. After decades of hard work, the company has formed four major businesses, and the company's customer base is more focused on cost and environmental protection due to its management practices, high-quality resources, and mostly listed companies. This makes low-temperature energy-saving powder coatings more widely available.

Guangdong Ajia's new low-temperature energy-saving paint breaks through the traditional thinking and conforms to the trend of low-carbon development, and truly contributes to the country's development of a low-carbon economy.

This technology is the industry leader, the first in China, and the market recognition and popularization momentum is strong. The company's top management attaches great importance to technology development, investing heavily in new technology research and development, and automated production.

After years of hard work, we have developed three production bases in Guangdong, Wuhan and Liaoning to achieve national market coverage. In the future, we will truly become an industry benchmark enterprise and an advanced fully automated green environmental protection factory.